HOW TO DESIGN MODULAR SUPPORT SYSTEMS FOR EARTHQUAKE ZONES

Products, services and software for seismic applications

THE PHYSICS OF AN EARTHQUAKE

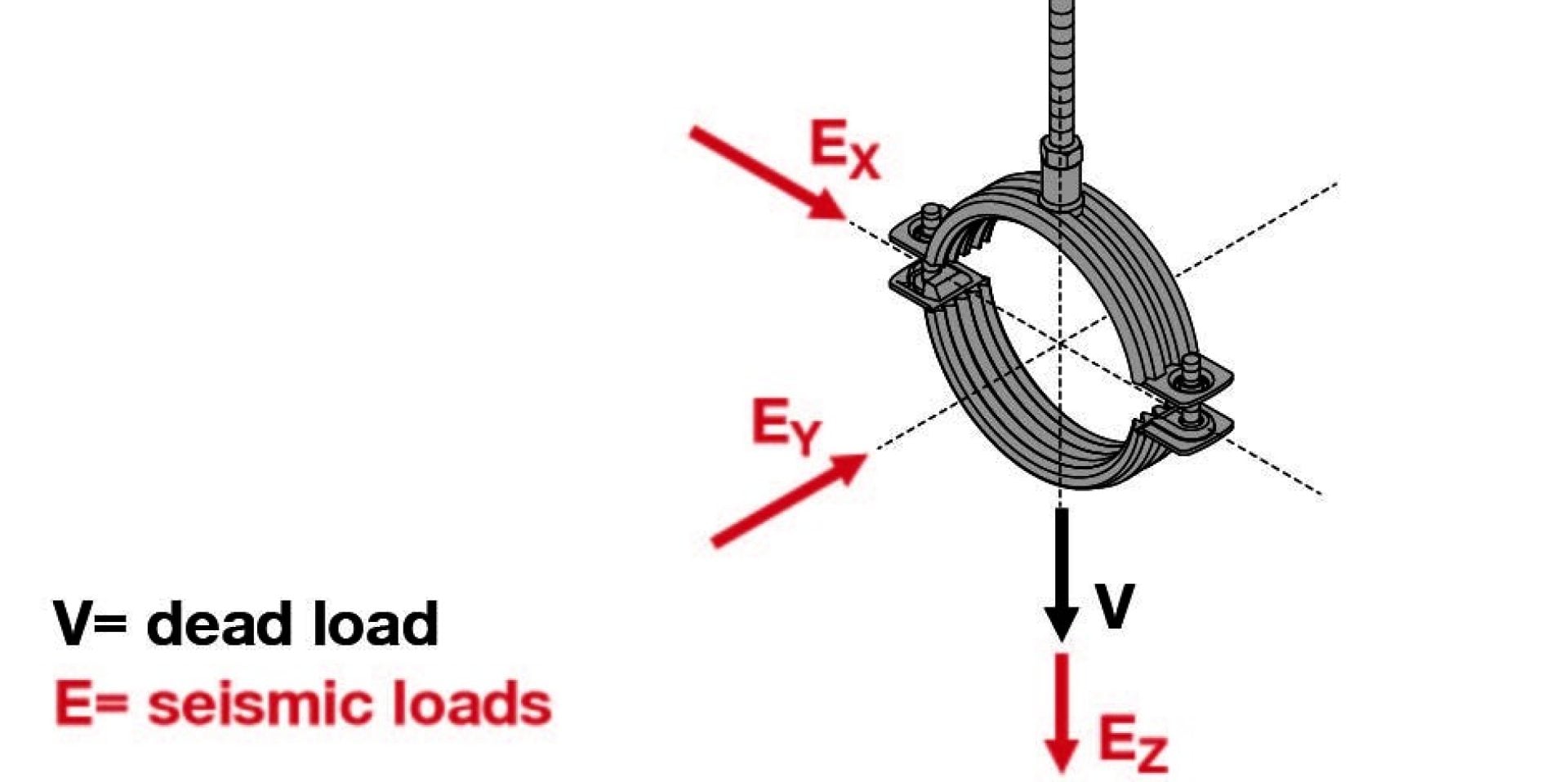

- An earthquake generates additional loads on the pipeline in all directions.

- Loads on the horizontal plane (Ex and Ey) are generally the most critical for the pipe support.

- Building codes (such as EC8, IBC) provide simplified methods to calculate the seismic loads based on an equivalent static analysis.

- According to most building codes the additional vertical seismic load does not need to be taken into account.

- To withstand these horizontal forces, modular support systems must be sufficiently rigid or designed with bracings arranged both in a longitudinal and transversal direction and suitably anchored to the base material.

QUICK LINKS

Share